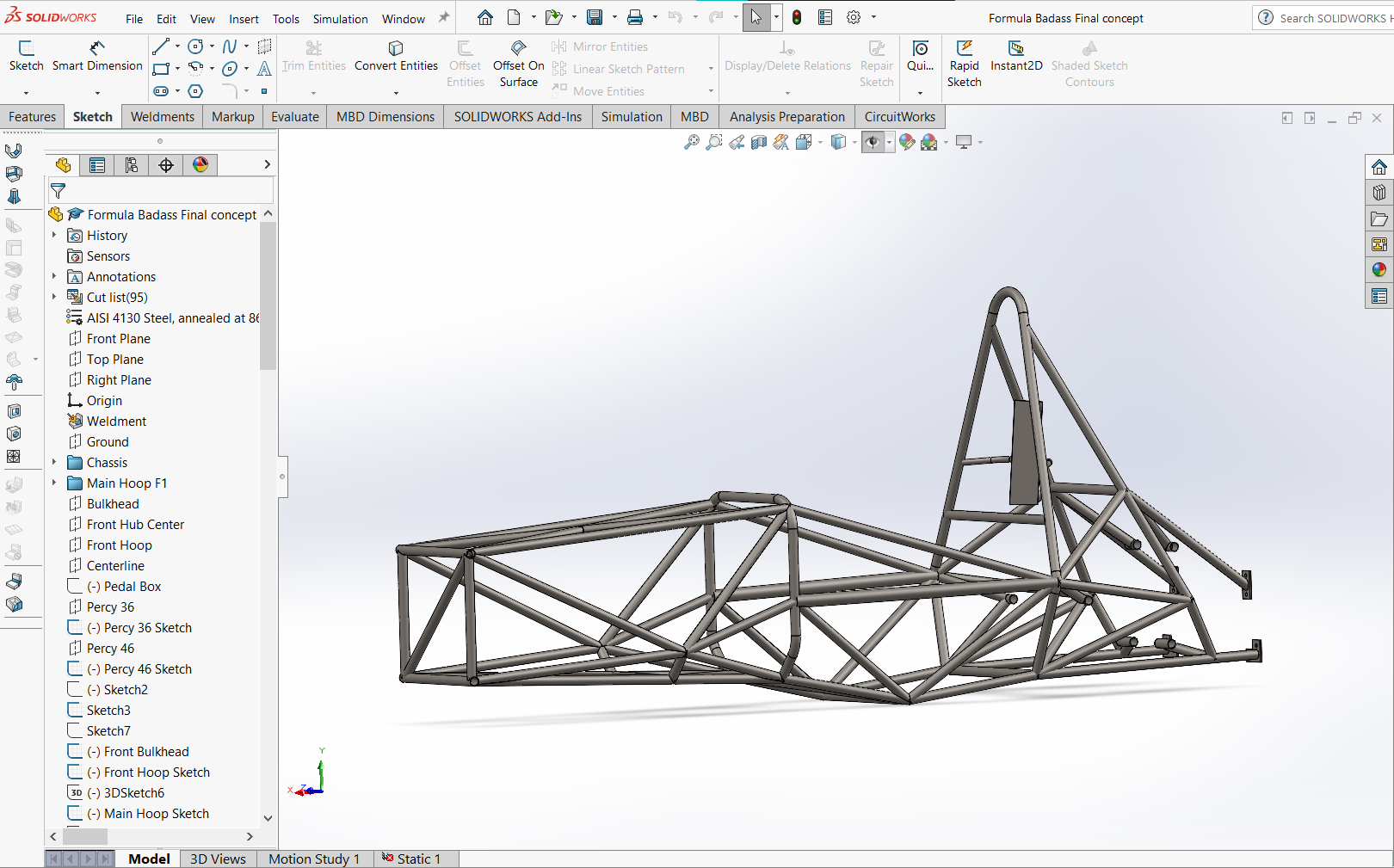

Final Design Arrival

After an exhaustive process of verifying complete vehicle agreement, ensuring competition compliance, ulitmate subsystem agreeability, meeting suspension objectives, and subjecting the chassis design to countless simulations, we have arrived at the final chassis design. This milestone is monumental and has given the team a boost in moving into the manufacturing phase.

A sample of the standards and codes that the chassis must follow concerning driver positioning safety and chassis internal cross sections.

After carefully verifying rule and subsytem compliance, the team strategically triangulated, braced and reinforced areas of the chassis, to land at a final design. The chassis exhibits the following characteristics.

Torsional Rigidity Test

Yield Strength 460 MPa

Max Stress 240 MPa

SF about 1.9

Precision-engineered mounts have been meticulously crafted to cradle the engine, and the entirety of the drivetrain in our final chassis design. These mounts are designed to provide optimal support, ensuring stability and minimizing vibrations during vehicle operation. Careful consideration has been given to the integration of engine components, guaranteeing a secure fit and enhancing overall drivetrain performance.

The journey involved meticulous checks to ensure compliance with competition regulations, seamless integration with subsystems, and the fulfillment of suspension objectives. Through extensive simulations, the chassis design underwent rigorous testing to validate its structural integrity and performance capabilities.

Moreover, the design successfully accommodates all engine components, demonstrating a holistic approach to vehicle integration. The synergy achieved between aerodynamic considerations and the chassis design enhances overall performance, contributing to an optimized and efficient final product.

This finalization represents a culmination of precision tailored engineering, iterative testing, and collaborative efforts across various disciplines. It marks a significant step toward realizing our vision of a high-performance vehicle that not only meets but exceeds expectations in terms of competition, functionality, and aerodynamic efficiency. The thorough validation process ensures confidence in the reliability and performance of the final chassis design as we move forward in the production phase.

Our chassis design has been engineered with a collaborative spirit, allowing for seamless integration with requests from the Aero department. Embracing their aerodynamic concept, the chassis has been structured to accommodate and complement their specifications. This collaborative approach enables the Aero team to work with a chassis that not only meets their requirements but enhances the overall aerodynamic efficiency of the vehicle. The simulation to the left showcases the max drag on the vehicle without aero components. The angle of the nose and ability for air to flow under the vehicle were highly requested items, that the chassis team was able to achieve.