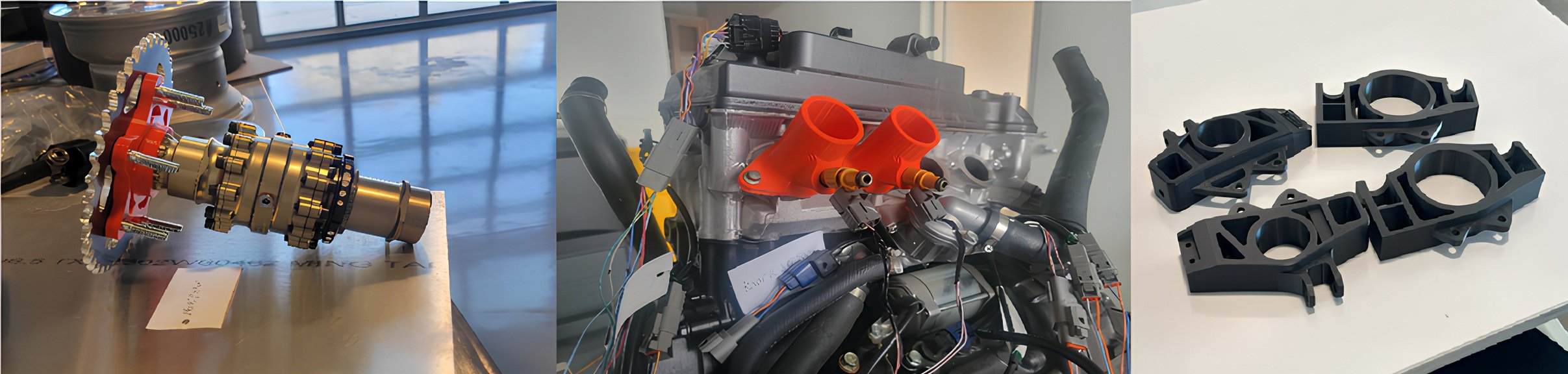

3D printing to Advance Manufacturing Efforts

Our team utilizes 3d printing to increase confidence and verify running tolerances and fitment before manufacturing components. 3D printing has accelerated prototyping, enabling rapid iteration and cost-effective testing. It ensures precise fitment, allowing us to assess design viability efficiently. By quickly translating digital concepts into physical models, 3D printing expedites the evaluation process, enhancing product quality and reducing time-to-market. We have utilized this extensively on some of our most elaborate and critical components. Parts such as our intake and our suspension uprights require precision fitment and verification with other components.